Ferro Silicon, an alloy of iron and silicon, is a critical element in steel production. This deoxidizes steel by removing oxygen from molten steel, making it strong and flexible. With India witnessing a robust growth of its steel industry supported by infrastructure development and a thriving automotive sector, the demand for ferrosilicon is on an upward trajectory. But the big question is; will the ferro silicon price in India follow suit by melting down?

Manufacturing Ferro Silicon

Submerged electric arc furnaces used in the Ferrosilicon making process. In this process, quartz, mineral rich in silicon dioxide (SiO2), and coke, a coal derivative high in carbon. The temperatures produced by the electric arcs in excess of 1500°C break up the SiO2 molecules. Silicon atoms released then combine with iron, which is also found in the charge to form ferro silicon. The silicon content of this final product varies depending on its desired application in steel making. Ferro silicon having low sum of silicon content (typically 45-75%) is used for deoxidation during steel production whereas that of high sums (up to 90%) are employed for specific applications such as grain refining and improving electrical properties of steel.

Global and Indian Demand & Supply

China is the world’s largest producer of ferrosilicon, followed by Russia and Norway. In 2022, China produced around six million metric tons of silicon, which is nearly two-thirds of the global production that year. The Indian ferro alloy industry has a capacity of 5.15 million tons, and accounts for nearly 10% of the world’s ferro alloy production.

The global steel industry has experienced steady growth over the years, driving demand for Ferro Silicon upward. It is an alloy used in deoxidizing and alloying of steels to improve their strength and durability. Furthermore, it is applied not only among other areas but also within industries like metallurgy, foundries and welding.

India commands a significant share of Ferrosilicon market due to it being one of largest producers of steel across the globe. This need has been propelled by ambitious infrastructure projects in the country coupled with strong industrialization efforts here.

Furthermore, the automotive and construction industries as well as their close association with steel are the major consumers of Ferro Silicon.

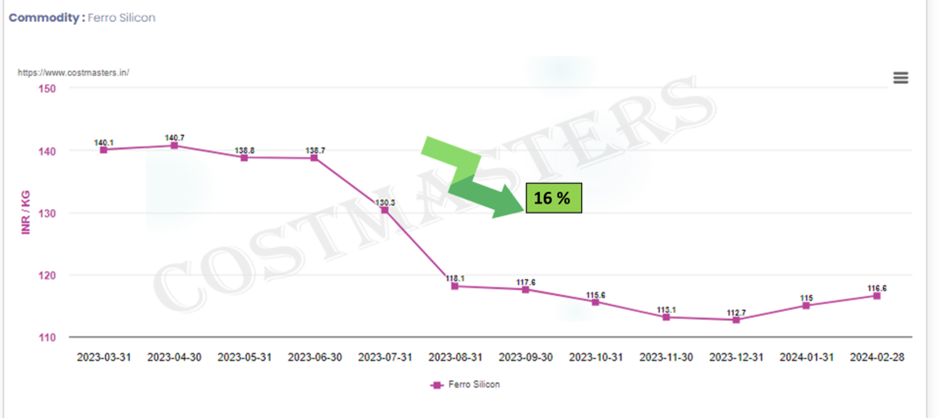

2023 Price Movements

Throughout the year 2023, ferro silicon prices in India and globally had an unpredictable path. After March 2022, prices have been on a downward trend with some fluctuations due to other factors. Some of the reasons for this fall are decreased demand, increased production and reduced costs.

The price of ferro silicon is largely dependent on steel sector’s demand. Increased consumption in that sector saw a slump in global economy leading to a low demand for steel resulting to lower prices of ferro silicon.

Forecasting of Prices

Demand-Supply Dynamics: Demand for steel and ferrosilicon is expected to remain strong in light of continuing infrastructure projects and industrialization programs underway. However, intermittent production constraints can be caused by challenges from the supply side which include raw material availability and regulatory pressures.

Raw Material Costs: The prices of key inputs like quartz, coal and electricity fluctuate hence affecting the cost of producing ferrosilicon thus leading to a change in prices. Market players must therefore employ efficient sourcing strategies as well as adopting technological innovations to cope with cost pressures.

Global Economic Trends: Ferro silicon price will still be influenced by macroeconomic indicators and geopolitical developments. Economic downturns, trade disputes, fluctuating currencies all create waves across commodity markets thereby determining price trends

The Ferro Silicon market of India is at a point where growing demand meets supply-side issues and global market dynamics. Still, short term price volatility may continue even as measures are being put in place by those in industry to counteract the vulnerabilities of the production chain and improve effectiveness of production processes; this could make prices more stable in the future. The Ferro Silicon market remains an important benchmark for India’s economic resilience and flexibility as it moves towards ambitious growth objectives.

Leave a comment